Process Development

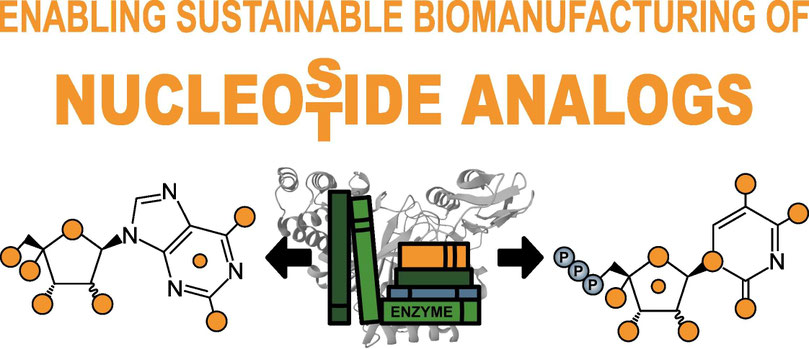

At BioNukleo we offer complete development of a sustainable biocatalytic manufacturing process for nucleoside or nucleotide analogs. From enzyme discovery to process transfer — we manage the entire process development procedure, combining biocatalyst selection, proof of concept, analytical development, process intensification, scale-up, and sample production to deliver robust and scalable biocatalytic processes.

Typical workflow

Our process development service is a work package based approach and can be fully customized to your specific standards, capabilities, or challenges. We thrive to supply you with the best possible process — tailored, sustainable, operable.

Research & Concept

Library screening

Route scouting

Presentation of process concept

Optional:

Database/Literature search

New biocatalyst identification, production, and characterization

Process Intensification

Strategic optimization of reaction conditions

Increase of product yield and concentration

Development of analytical methods

Optional:

Accomodating specific customer requirements

Production of test samples

Validation of product quality

Delivery of up to 10 g product

Optional:

Optimization of downstream processing

Tech Transfer

Transfer of Operating Procedure

Teaching

Optional:

Scaling of biocatalyst production

On-site support

Our enzyme library

Our library of well-characterized biocatalysts enables fast and confident identification of the right enzyme for your target reaction. Produced in-house, our purified biocatalysts ensure consistent quality, flexible customization, and reliable supply. By using wild-type and often thermostable enzymes, we minimize side reactions, improve yields, and deliver reproducible results even under demanding conditions. This precision-driven approach accelerates your research and leads to cleaner, more efficient biocatalytic processes.

Enzymes produced and characterized in-house

-

Controlled expression: Optimized vectors ensure reliable production in E. coli, B. subtilis, or P. pastoris.

-

Scalable production: From microplates to bioreactors, even for difficult-to-express proteins.

-

Thoroughly characterized: Every enzyme is researched and validated in-house. This deep understanding guarantees predictable performance, reproducibility, and confidence in every reaction.

Why purified enzymes?

Enhanced control: Purified systems allow for precise adjustment of reaction conditions and cofactor balance.

Cleaner results: High enzyme purity eliminates unwanted background reactions which results in improved yields, simplified analytics, and less downstream effort.

Better reproducibility: Defined enzyme quality ensures consistent performance across batches.

Why wild-type enzymes?

Fast project start: Wild-type enzymes enable quick proof-of-concept and reduce development time.

Secure FTO: Using natural enzymes ensures freedom to operate without IP restrictions.

Robust performance: Naturally evolved catalysts offer reliable activity and typically solid stability.

Why thermostable enzymes?

Extended lifetime: Thermostable proteins typically display a generally greater stability towards harsh conditions.

Robust performance: High thermostability ensures reliable activity under high-temperature conditions - which positively influences substrate solubility and reaction times.

Simplified processing: Thermostable enzymes allow for easier handling and purification.

Explore what's possible

Explore in the list below what is currently accessible via BioNukleo's extensive enzyme library. Any of these products have been screened before and can be readily produced with our enzymatic platform. However, our capabilities go far beyond this selection. If your desired molecule isn’t shown, it simply means it hasn’t been explored yet — not that it can’t be done.

Ready to turn your ideas into a reliable, sustainable biocatalytic process? Connect with us and explore your tailored solution.